Links:

-

In conclusion, annealed float glass is a versatile, affordable, and customizable option for a wide range of applications. Its strength, durability, and aesthetic appeal make it a popular choice for residential, commercial, and industrial projects. However, it is essential to consider the specific requirements of each application to determine the most suitable type of glass for the project. The process of tempered acid-etching involves several steps. First, the glass is heated to a high temperature to soften it, a process called annealing. Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking

Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking

Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking tempered acid etched glass. After tempering, the glass is etched using a mixture of acid and water. The acid eats away at the glass, creating the desired design, while the water helps to remove any residue left behind.

tempered acid etched glass. After tempering, the glass is etched using a mixture of acid and water. The acid eats away at the glass, creating the desired design, while the water helps to remove any residue left behind.

annealed float glass. It can be cut, shaped, and polished to meet specific size and design requirements. This flexibility in customization makes it a popular choice for architects, designers, and homeowners who are looking to create unique and visually appealing spaces. When you look into a silver traditional mirror, you can't help but feel a sense of wonder and awe at the beauty and craftsmanship that went into creating such a stunning piece. The silver frame reflects light in a way that is both luxurious and captivating, making it the perfect addition to any room The silver frame reflects light in a way that is both luxurious and captivating, making it the perfect addition to any room

The silver frame reflects light in a way that is both luxurious and captivating, making it the perfect addition to any room The silver frame reflects light in a way that is both luxurious and captivating, making it the perfect addition to any room

The silver frame reflects light in a way that is both luxurious and captivating, making it the perfect addition to any room The silver frame reflects light in a way that is both luxurious and captivating, making it the perfect addition to any room silver traditional mirror. 1. **Accuracy** Professional installers have the tools and expertise to measure and cut the new IGU precisely, ensuring a tight fit and optimal performance. In conclusion, OEM tempered glass is the ultimate protection for your devices. Its strength, clarity, and scratch resistance make it an essential accessory for anyone who wants to keep their devices safe and looking great. So why wait? Protect your investment today with OEM tempered glass. The use of patterned glass sheets also extends to exterior applications, such as windows and patio doors, where they offer a degree of obscurity while still permitting views of the outside world. They provide a layer of sophistication to any facade, subtly hinting at the elegance within. The Cost of Tempered Glass A Worthy Investment The Ming (1368-1644) and Qing (1644-1912) Dynasties further embellished the silver mirror tradition

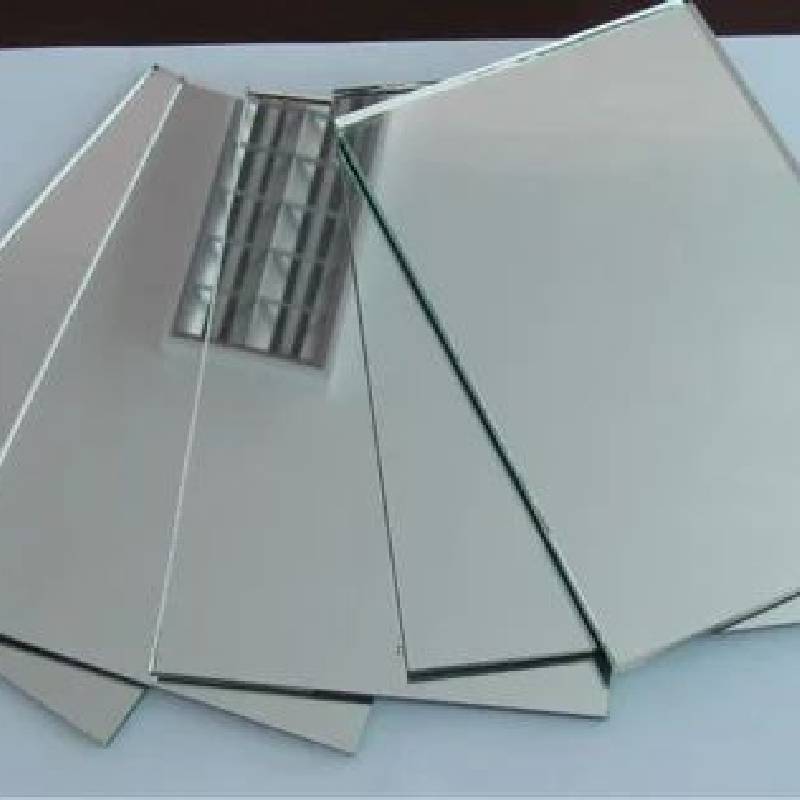

silver traditional mirror. 1. **Accuracy** Professional installers have the tools and expertise to measure and cut the new IGU precisely, ensuring a tight fit and optimal performance. In conclusion, OEM tempered glass is the ultimate protection for your devices. Its strength, clarity, and scratch resistance make it an essential accessory for anyone who wants to keep their devices safe and looking great. So why wait? Protect your investment today with OEM tempered glass. The use of patterned glass sheets also extends to exterior applications, such as windows and patio doors, where they offer a degree of obscurity while still permitting views of the outside world. They provide a layer of sophistication to any facade, subtly hinting at the elegance within. The Cost of Tempered Glass A Worthy Investment The Ming (1368-1644) and Qing (1644-1912) Dynasties further embellished the silver mirror tradition The functionality of patterned glass extends beyond mere decoration. Privacy is enhanced when used in bathrooms or conference rooms, allowing natural light to filter through without sacrificing occupants' privacy. Furthermore, patterned glass can provide a degree of soundproofing, making it ideal for noisy environments where a sense of tranquility is desired. Mirror glass is a key element in any home decor, adding depth, brightness, and style to any room. Whether you are looking to enhance the aesthetic appeal of your living space or simply looking for a practical solution, mirror glass for sale offers a wide range of options to suit your needs.

The functionality of patterned glass extends beyond mere decoration. Privacy is enhanced when used in bathrooms or conference rooms, allowing natural light to filter through without sacrificing occupants' privacy. Furthermore, patterned glass can provide a degree of soundproofing, making it ideal for noisy environments where a sense of tranquility is desired. Mirror glass is a key element in any home decor, adding depth, brightness, and style to any room. Whether you are looking to enhance the aesthetic appeal of your living space or simply looking for a practical solution, mirror glass for sale offers a wide range of options to suit your needs. Moreover, low-E glass contributes to sustainability and energy conservation. By reducing reliance on heating and cooling systems, buildings use less energy, which can lead to a decrease in greenhouse gas emissions. As society becomes increasingly aware of the importance of environmental stewardship, incorporating low-E glass into building designs aligns with global efforts to promote sustainability and combat climate change.

One of the key advantages of tinted black glass is its ability to regulate light and heat transmission. By controlling the amount of sunlight that enters a building, tinted black glass can help to reduce energy costs associated with cooling and heating. This makes it an environmentally friendly choice for those looking to minimize their carbon footprint.

The Rise of Pattern Glass Suppliers Innovations and Trends in Decorative Glass

Tinted glass, also known as colored glass, is a type of glass that has been treated with a special coating to give it a specific hue. This type of glass has become increasingly popular in recent years, as it adds a touch of style and sophistication to any space. Whether it is used in windows, doors, or even furniture, tinted glass can completely transform the look and feel of a room.

Tinted float glass is a versatile building material that combines aesthetic appeal with functional characteristics, making it an increasingly popular choice in various construction and design projects. The tinting process involves adding metal oxides to the molten glass during production, resulting in a finished product that is not only visually striking but also provides essential benefits, such as glare reduction, UV protection, and thermal insulation.

From an environmental perspective, the use of Low-E2 glass supports sustainability initiatives. Buildings account for a significant portion of energy consumption and greenhouse gas emissions. By incorporating energy-efficient materials like Low-E2 glass, architects can help mitigate these impacts. Furthermore, many Low-E glass products are made from recycled materials, reducing the overall ecological footprint of construction projects.

As we look ahead, the future of glass manufacturing appears bright. With a commitment to sustainability, ongoing innovation, and a focus on customer needs, these companies are poised to continue shaping our built environment and everyday lives in exciting ways. From architectural marvels to high-tech gadgets, the potential applications for glass seem endless, ensuring that this age-old material remains relevant and valuable well into the future. The essence of reflective brown glass lies in its ability to reflect light while maintaining a subtle warmth and depth. The brown tint imparts a sense of earthiness and sophistication, evoking feelings of comfort and tranquility. Its reflective property, on the other hand, offers a practical advantage, enhancing energy efficiency by reducing heat absorption and glare. In urban landscapes, where sunlight management is crucial, reflective brown glass proves to be an ideal choice for building facades. Toughened float glass is also more scratch-resistant than standard glass, making it ideal for use in high-traffic areas where the glass is prone to scratches and abrasions. The toughened surface of the glass helps to maintain its clarity and transparency over time, making it a cost-effective option for applications that require high visibility and aesthetics. Low reflective glass is also known for its durability and longevity. It is typically coated with a special anti-reflective coating that helps to protect the glass from scratches, stains, and other damage. This makes it a practical choice for high-traffic areas or places that are exposed to the elements. During summers, Low-E glass prevents the scorching heat from entering the building, keeping interiors cool and comfortable. In winters, it retains the warmth inside, minimizing heat loss and lowering heating costs. Thus, it plays a crucial role in maintaining a consistent indoor temperature, enhancing energy efficiency, and contributing to a greener lifestyle. Overall, insulated window units are a great investment for homeowners looking to improve the energy efficiency, comfort, and overall value of their homes. Whether you are looking to save money on your energy bills, reduce outside noise, or improve the comfort of your home, insulated window units are a great choice. Consider installing insulated window units in your home today to start enjoying the many benefits they have to offer. Float glass is primarily composed of about 70% silica (sand), 13% soda ash (sodium carbonate), and 12% limestone (calcium carbonate), with small amounts of other materials added for specific properties such as color or durability. Its uniform thickness and optical clarity make it ideal for a wide range of uses. The Cost of Tempered Glass per Square Foot An In-Depth Analysis Float glass is primarily composed of about 70% silica (sand), 13% soda ash (sodium carbonate), and 12% limestone (calcium carbonate), with small amounts of other materials added for specific properties such as color or durability. Its uniform thickness and optical clarity make it ideal for a wide range of uses. One of the key benefits of aluminum wall mirrors is their durability. Unlike traditional glass mirrors, aluminum mirrors are less likely to shatter or break, making them a safer option for households with children or pets. Additionally, aluminum mirrors are lightweight and easy to install, making them a practical choice for any room in your home.

Nevertheless, it is essential to consider the type of low-E glass that best suits specific needs. Low-E glass comes in various types, including hard-coat and soft-coat options. Hard-coat low-E glass has a thicker, more durable coating but may reflect slightly less natural light. Soft-coat low-E glass, on the other hand, offers superior performance in terms of insulation and visibility, making it a preferred choice for high-performance applications.

But the king knew that the true power of the Silver Scroll Mirror lay not in its ability to reflect physical features but in its capacity to reveal the inner workings of the human heart

silver scroll mirror. He therefore instructed his advisors to use the mirror to uncover the truth behind various disputes and conflicts within the kingdom. The mirror proved to be an invaluable tool, helping to resolve misunderstandings and bring harmony to the land. In conclusion, tinted laminated glass offers a range of benefits that make it a versatile and practical choice for a wide variety of applications. From energy efficiency and safety to privacy and aesthetic appeal, tinted laminated glass is a smart investment for any building project. Whether used in windows, doors, partitions, or facades, tinted laminated glass is sure to enhance the comfort, security, and style of any space. Furthermore, low e reflective glass is durable and long-lasting, requiring minimal maintenance over time

silver scroll mirror. He therefore instructed his advisors to use the mirror to uncover the truth behind various disputes and conflicts within the kingdom. The mirror proved to be an invaluable tool, helping to resolve misunderstandings and bring harmony to the land. In conclusion, tinted laminated glass offers a range of benefits that make it a versatile and practical choice for a wide variety of applications. From energy efficiency and safety to privacy and aesthetic appeal, tinted laminated glass is a smart investment for any building project. Whether used in windows, doors, partitions, or facades, tinted laminated glass is sure to enhance the comfort, security, and style of any space. Furthermore, low e reflective glass is durable and long-lasting, requiring minimal maintenance over time

low e reflective glass. This makes it a cost-effective solution for building owners looking to invest in high-quality materials that will stand the test of time.

The Surface Silvered Mirror A Reflection of Art and Science

Bamboo, a symbol of strength and flexibility, has been used in various cultures for centuries. Its natural beauty and versatility have made it a popular material for all kinds of products, including mirrors. When combined with silver, a precious metal known for its elegance and shine, bamboo creates a stunning and unique piece of décor that can elevate any space.

Grey float glass is also highly durable and resistant to scratching and fading Exploring the World of Acid-Etched Glass Suppliers One of the most significant aspects of 8mm film is its size. At just 8 millimeters in width, it is significantly smaller than other film formats like 16mm and 35mm. This compact size not only made it more portable but also more accessible to amateur filmmakers and hobbyists. The reduced film gauge also meant that each roll could capture more footage, making it ideal for creating short films and home movies.

One of the key advantages of float glass manufacturing is its efficiency. In a typical float glass factory, the entire production process is highly automated. From the melting of raw materials—which typically includes silica sand, soda ash, and limestone—to the cutting, annealing, and packaging of finished glass sheets, modern technology ensures high precision and minimal waste. This automation not only speeds up the production cycle but also significantly reduces labor costs while maintaining product quality.

The Enchanting World Behind Reflective Float Glass In conclusion, low e reflective glass is a smart choice for anyone seeking to upgrade their building's windows or glass features. With its energy-efficient properties, durability, and aesthetic appeal, this innovative glass material is sure to provide lasting benefits for both residential and commercial applications. Conclusion Crafted with meticulous attention to detail, the Valentia Silver Mirror is a testament to the skilled hands of artisans who have honed their craft over generations. The intricate patterns etched onto its frame, each line and curve meticulously carved, tell a story of timeless beauty. These designs, often inspired by nature or historical motifs, create a visual narrative that is both captivating and thought-provoking. Indeed, the aluminum wall mirror transcends mere embellishment; it is an understated piece of art that speaks volumes about modern taste and lifestyle. With its capacity to embellish spaces with a touch of elegance and sophistication, it remains a cherished element in the ever-evolving narrative of home decor.